AN956 AN912 AN923 AN934

Anionic polyacrylamide (APAM) series products are water-soluble linear polymers synthesized with a high degree of polymerization. Supplied in the form of microgranules or colloids free-flowing without dust and flakes, it is completely soluble in water and, due to its microgranular form, dissolves rapidly. Different types of polyacrylamides have different active groups, which can flocculate different suspended particles for easy filtration and separation. Polyacrylamide is almost insoluble in any organic solvents and largely soluble in water. It is widely used in flocculation, thickening, bonding, scale inhibition, colloid stabilization, drag reduction, film formation, gel and biological materials in many industries. The appearance of the anionic polyacrylamide PAM produced by our factory is white dry powder or granules, and the effective pH range is 7-14. According to different uses, it is divided into two production processes, one is homopolymerization (pre-hydrolysis of non-ionic polyacrylamide), and the other is A copolymer (acrylamide and acrylic acid or sodium acrylate).

The main purpose:

1. Industrial wastewater treatment: For suspended particles, coarse, high concentration, positively charged particles, neutral or alkaline wastewater with pH value of water, steel mill wastewater, electroplating factory wastewater, metallurgical wastewater, coal washing wastewater and other sewage treatment , the effect is good.

2. Drinking water treatment: Generally, it is better to use anionic polyacrylamide (flocculant). The water sources of many waterworks in my country come from rivers, which contain high sediment and minerals and are relatively turbid. Although they have been filtered through sedimentation, they still cannot meet the requirements, and flocculants need to be added. In the past, inorganic flocculants were mostly used in water plants, and the dosage was 1/50 of that of inorganic flocculants, but the effect was several times that of inorganic flocculants. For river water with serious organic pollution, it is better to use the inorganic flocculant polyaluminum chloride and the cationic polyacrylamide produced by our company.

3. Recycling of lost starch wine tanks in starch factories and alcohol factories: Now the wastewater of many starch factories contains a lot of starch. Now add anionic polyacrylamide to flocculate and precipitate starch particles, and then filter the precipitate into a cake shape, which can be used as feed. The wine tank of the alcohol factory can also be recovered by cationic dehydration and pressure filtration.

4. Used as dry strength agent for papermaking.

5. Papermaking additives: In the papermaking industry, anionic polyacrylamide (PAM) is used as clarification of caustic soda, fiber dispersant, can improve beating degree, filler retention aid, paper strengthening agent, can be used to improve water filtration rate and clean water recovery. Adding a small amount of PAM-03 anionic polyacrylamide in the pump-mouth pulp storage tank before papermaking can increase the retention of fillers and fine fibers in the net by 20-30%. 20-30kg of pulp can be saved per ton.

6. Oil displacement agent for tertiary oil recovery in oilfields: anionic polyacrylamide can adjust the rheology of injected water, increase the viscosity of driving fluid, improve the water flooding efficiency, reduce the water phase permeability in the formation, and enable water and oil to flow uniformly front flow. Its function is mainly used in the tertiary oil recovery of oil fields in terms of oil exploitation. For every ton of polymer polyacrylamide product injected, an additional 100-150 tons of crude oil can be recovered.

7. Drilling mud material: In the exploration and development of oil fields and the exploration of geology, water conservancy and coal, anionic polyacrylamide is used as an additive for drilling mud materials, which can increase the service life of drill bits, increase drilling speed and footage, and reduce the time for changing drills blockage, and the effect of preventing well collapse is obvious. Fracturing fluid for polyacrylamide oilfields and water shutoff agent for profile control and water shutoff.

Illustrate:

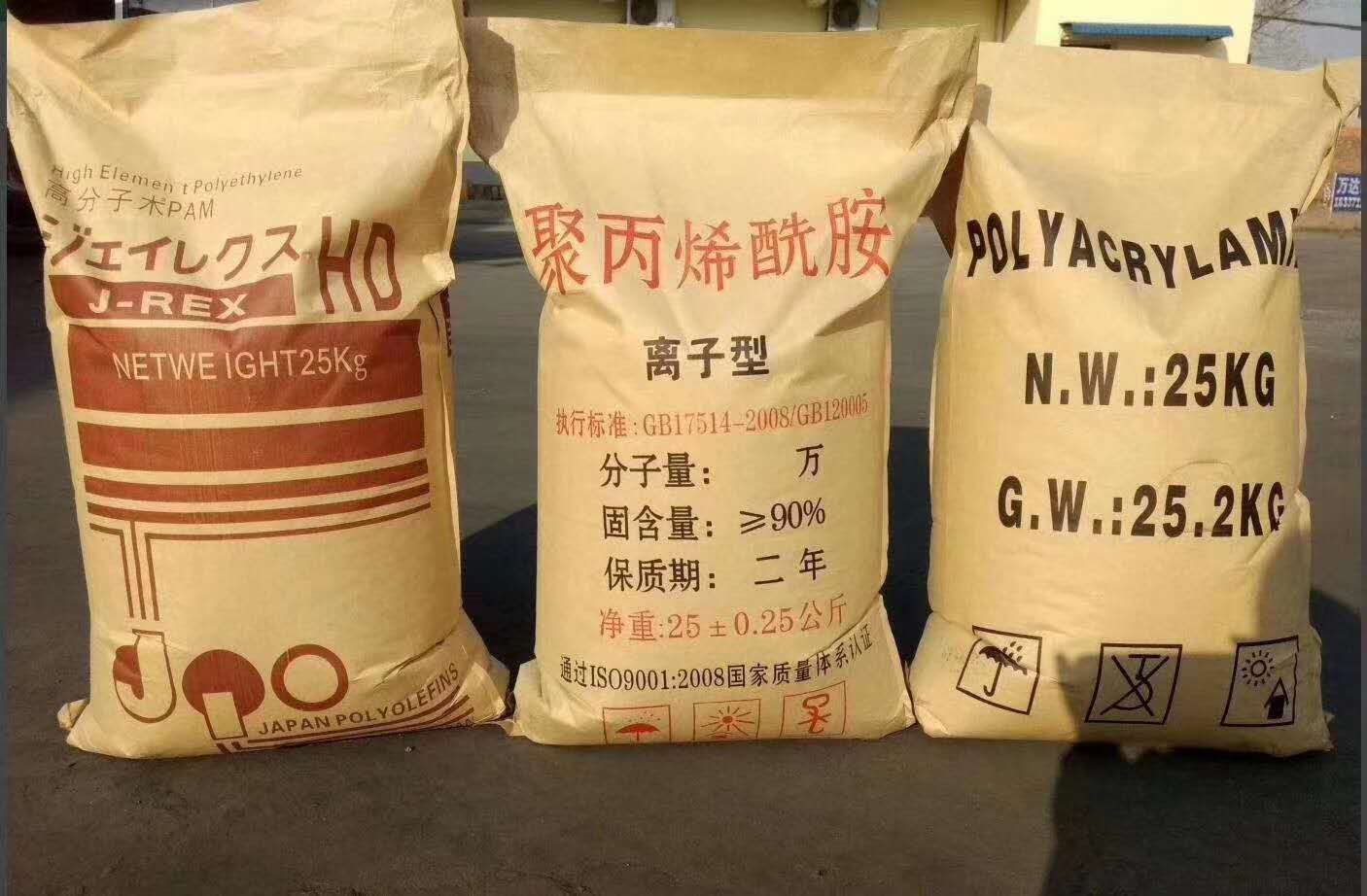

1. The packaging of this product is a woven bag lined with double-layer polyethylene plastic bags or plastic-coated kraft paper. The net weight of each bag is 25kg.

2. Pay attention to heat and moisture protection during storage and transportation. Dry powder products will absorb moisture and agglomerate if left exposed for a long time.

3. The number of stacking layers shall not exceed 20, and the effective storage period is 2 years.

4. The particle size of this product is 20-80 mesh, and it can also be produced according to user requirements.