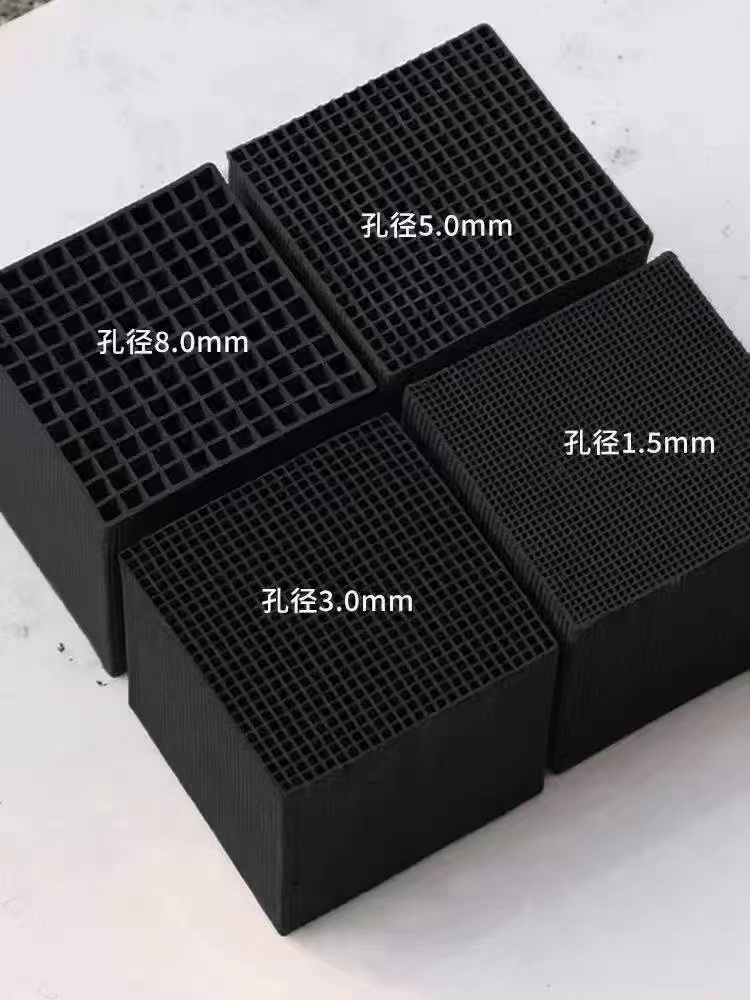

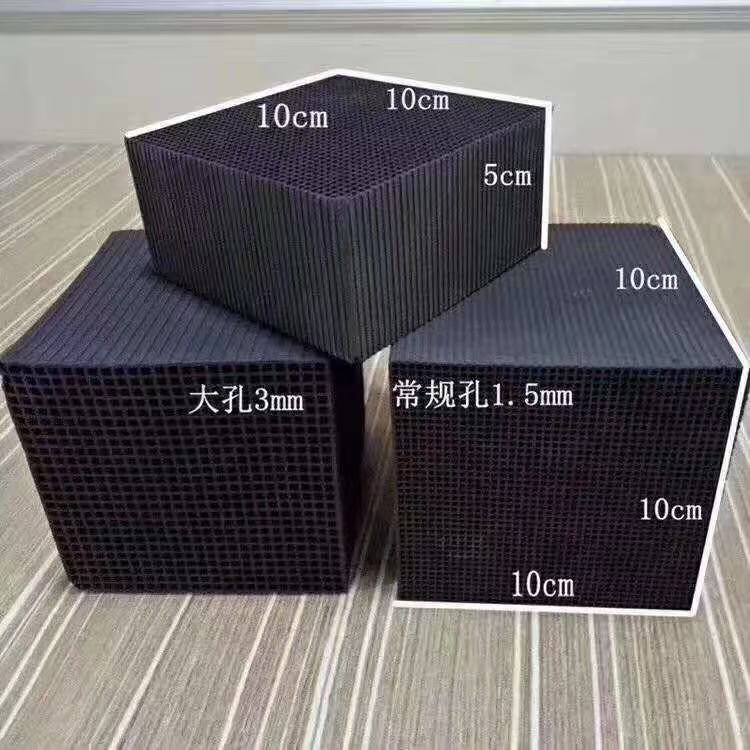

Waterproof activated carbon honeycomb blocks 50*50*50mm or 100*x100*x50mm for air filtration purposes

Honeycomb-like activated carbon is a new type of absorption material made by high quality powder activated carbon and binder. Honeycomb carbon block has a large amount of through holes from one end to another end in a cubic or cylindrical shaped block. Honeycomb carbon filter is a type of high effective carbon filter to remove unpleasant odors, particulates and other pollutants.

This kind of structure gives low pressure drop, high mechanical strength and more contact surface with gas. Honeycomb carbon block is mainly used for vapor phase pollutants removal. Now it is widely use for air purification system which is high flow rate, low-concentration VOC pollutant air streams

Consider the following features and advantages of using Honeycomb carbon block over traditional pellet and granular activated carbons:

1. The honeycomb structure has a pore size range of 10-2,000 Angstroms and a BET surface area range of ~200-3,000 sq.m/gm!

2. The honeycomb carbon block is desorbed with liquid ring vacuum pumps and a small quantity of heated condensation compound free air – the adsorbed compounds are stripped!

3. The pressure drop at a given linear gas velocity for Honeycomb carbon block containing 200 cpsi (cells per square inch) is 11 times lower than densely packed 4mm pellet extruded activated carbon!

4. Honeycomb structures may be pressed into cubes, round cylinders, oval, square and rectangular cylinders!

5. The shorter distances for internal diffusion mass transfer for honeycomb carbon leads to faster saturation and desorption rates and thus shorter cycle times!

6. Honeycomb adsorbent can be purged of fuel compounds and solvents using a vacuum above 100 mbar!

7. Honeycomb carbon has a much higher specific surface area compared to other carbon structures!

8. Honeycomb carbon block has a lower level of carbon attrition and dust-related problems due to carbon attrition are minimized!

9. Honeycomb carbon block is available in 100, 200, 300 or 400 cpsi!

10. Honeycomb block carbon is only 15% more expensive than 4mm pellets and has 3 times the surface area for adsorption!!

11. The honeycomb shape core mesh can be paperboard, plastic and aluminum material. The paperboard core mesh is the most economical products, but it is not reusable. The plastic and aluminum honeycomb core meshes are reusable and durable.

12. Honeycomb shape could be cubes, round cylinders, oval, square and rectangular cylinders.

13. Honeycomb carbon has a higher external surface area of adsorbent compare to granular carbon,it has 2X bigger contact areas for adsorption if using 100 CPSI, 4X if using 300 CPSI honeycomb.